Insulated xlpe cable has many advantages, but overheating has always been the main factor affecting the safe and reliable operation. Its operating temperature should not be greater than the maximum rated temperature. Although there have been many advances in the manufacturing process and structure of copper core xlpe cable, if the maximum rated temperature of electrical xlpe cable is exceeded for long-time during operation, it is still difficult to escape the fate of aging.

Here is the content list:

- What will happen when rated temperature of xlpe cable is exceeded?

- Why is the performance of xlpe cable affected by temperature?

- How to avoid xlpe cable overheating for a long time?

What will happen when rated temperature of xlpe cable is exceeded?

The safe operation of insulated xlpe cable is very important to the stability of the entire power system. Once the electric xlpe cable fails due to overheating, it will cause a major power outage in the area under its jurisdiction, and may also endanger the lives and properties of relevant personnel.

Of course, even in the allowable value range, the working life of the cable will be reduced due to other reasons, but their incidence rarely exceeds the overheating of the xlpe cable. As far as electrical insulation is concerned, temperature is one of the important factors affecting insulation characteristics.

According to cable operation and use experience, although the rated maximum operating temperature of xlpe cable may vary due to its material and process, it will basically not exceed 100 °C. If it does not exceed this rating, xlpe cable can operate safely for decades.

On the contrary, if the degrees of the xlpe cable is too high, it will cause the accelerated aging of its insulation and greatly shorten the life of the xlpe cable. It is often due to the weak factors in the cable line that the temperature exceeds the standard.

Why is the performance of xlpe cable affected by temperature?

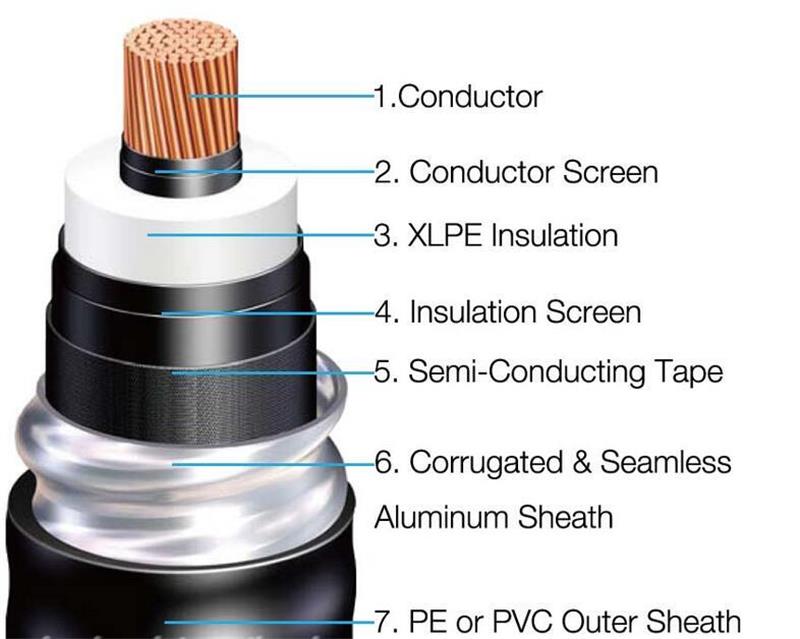

The cable constituent materials are divided into two parts: one is a conductor and the other is an insulator. The role of the xlpe cable conductor is to conduct current, so it will generate heat, and the greater the current, the greater the heat.

The insulator itself does not generate heat, but it is wrapped around the conductor, and the heat emitted by the xlpe cable conductor will be 100% transferred to the insulator, increasing the temperature of the insulator.

The conductor of xlpe cable is made of metal and is relatively afraid of high temperature, but the insulator is made of organic material, which is relatively afraid of high temperature. 100 °C or 200 °C will not have an excessive effect on the metal core, but the insulator will not be able to stand it.

In order to ensure that the insulator of the xlpe cable is not damaged due to high temperature, it is necessary to limit the heat generation of the conductor, that is, to limit the temperature of the conductor.

If the rated value is 90 °C, it means that the xlpe cable conductor can be kept at 90 °C for a long time without causing additional damage to the insulating material. It is also allowed to exceed it for a short time (but not too much); but if it is exceeded for a long time, Xlpe cable will inevitably age.

How to avoid xlpe cable overheating for a long time?

In the daily production work environment, xlpe cable has a very important use function, and its normal use directly determines whether the entire electricity environment meets the safety and stability standards. If the xlpe cable is aging or damaged, the power environment will be seriously affected, and accidents may even occur, so how can we prevent this from happening?

· Ensure the safe current carrying capacity

Pay attention to safe current carrying capacity when using xlpe cable. If the current seriously exceeds the safe carrying capacity of the xlpe cable, its temperature will be increased sharply, affecting the service life of the xlpe cable, and it is prone to tripping and short-circuit problems, which will naturally cause serious hidden dangers.

· Conduct regular maintenance

If you want to better prevent xlpe cable from aging and damage, in addition to paying attention to the safe carrying capacity, you must also pay attention to regular maintenance. Regular maintenance can find the problem in advance, and repair it when the xlpe cable does not cause greater losses to avoid affecting the normal use of the circuit.

Preventing the electric xlpe cable from overheating can make the circuit in the electrical environment more stable and avoid unnecessary trouble. People’s Cable Group Co., Ltd. hopes to prevent you from overloading for a long time by introducing you to the maximum rated temperature of waterproof xlpe cable. If you want to know more about the use of insulated xlpe cable, you can browse our website or consult our customer service.