With the increasing of electrical machinery, electrical xlpe cable has become more and more widely used. Related personnel continue to study and improve its design, manufacturing process, and test technology to ensure that insulated xlpe cable can operate more safely and stably. However, in recent years, with the extensive use of safe xlpe cable in urban construction and transformation, failure number has gradually increased.

Here is the content list:

- What are the advantages of xlpe cable in the electrical industry?

- Why the number of xlpe cable failures is rising?

- How to manage the life cycle of xlpe cable?

What are the advantages of xlpe cable in the electrical industry?

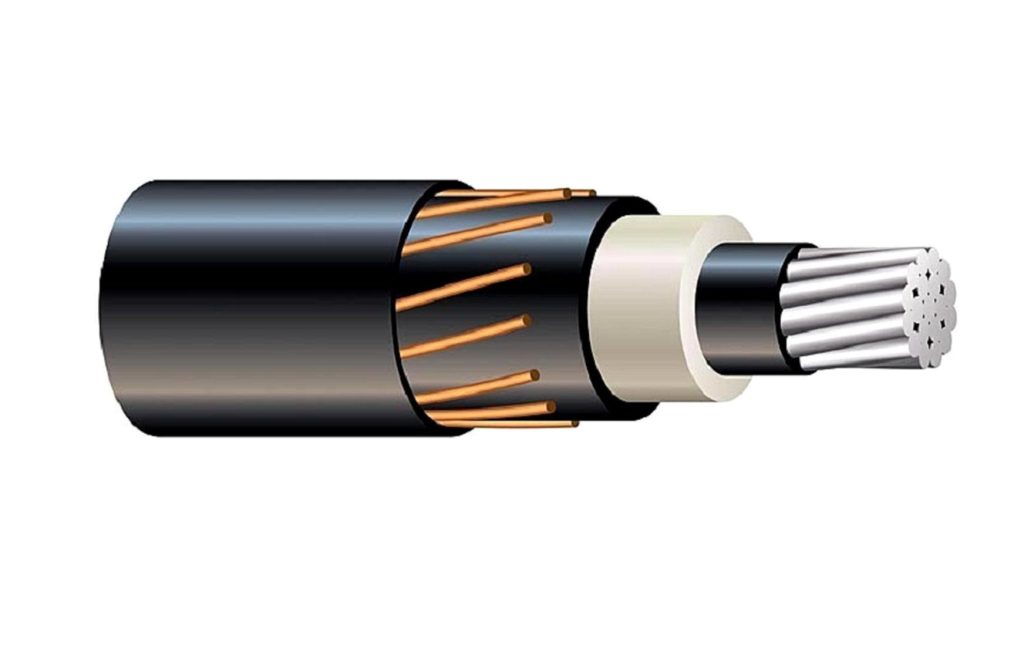

Insulated xlpe cable has many advantages, neat and beautiful, small footprint, no impact on the city appearance, power supply from which is less affected by the natural environment, and stable transmission performance, high reliability, so it is widely used in power systems.

Within the national distribution network, due to historical heritage and other reasons, copper core xlpe cables are used in large quantities, and aluminum core xlpe cables account for a relatively low proportion.

As the overall performance of aluminum is similar to that of copper, and aluminum is far superior to copper in terms of economy, in recent years, distribution networks in some areas have also begun to use aluminum core xlpe cable, which has become one of the main technological development directions of the current xlpe cable industry.

Why the number of xlpe cable failures is rising?

Due to the increasing demand for electricity in urban areas, the scale of power equipment has shown an expanding trend, and the number of outgoing circuits in substations has continued to increase.

At the same time, the density of urban buildings is also increasing, the demand for xlpe cable is becoming more and more extensive, and the pressure it bears has become heavier. Therefore, in areas where the electricity load of cities and towns is increasing rapidly, xlpe cables often work overloaded.

· Long time overload

Long-term overload operation will increase the temperature of the xlpe cable, and the insulation layer will age, so that the current can easily penetrate the insulation layer.

· Low construction quality

The construction process of xlpe cable does not meet the requirements, and the airtightness is poor, so that moisture can penetrate into the inside of the cable, which reduces the insulation performance.

It is also likely that the constructor fails to take protective measures when laying the xlpe cable, and the drainage is not smooth, so that the xlpe cable is soaked in water for a long time, which damages the insulation strength.

· External force damage

The main reason is the rude mechanical construction in municipal construction, which may destroy the xlpe cable.

· Corrosion

The protective layer of xlpe cable suffers from chemical corrosion or electric corrosion for a long time, which causes the protective layer to fail and cause accidents.

How to manage the life cycle of xlpe cable?

In the selection of xlpe cable, it is necessary to purchase in strict accordance with the prescribed standards. The insulation of xlpe cable must be complete and the size must meet the standard. The electrical and mechanical properties of xlpe cable must meet the requirements of long-term operation. For this reason, it is necessary to choose a professional and honest manufacturer.

The laying of xlpe cable must be carried out by strictly trained technicians in accordance with the corresponding installation specifications, and the insulation shield shall not be stripped.

At the same time, pay attention to the smoothness of the outer shield fracture. The installation of xlpe cable should be carried out in an environment with no pollution and low humidity.

In addition, when the operating environment and operating load of the xlpe cable change drastically, for example, the xlpe cable originally laid in a humid environment changes to a dry environment and changes from light load to full load operation. It is recommended that load changes before and after the xlpe cable partial discharge changes be monitored.

The aging of the insulation of insulated xlpe cable will lead to a gradual decline in electrical performance and heat resistance. Therefore, regular monitoring and maintenance of xlpe cable is very important. You can give this work to People’s Cable Group Co., Ltd., as a professional xlpe cable manufacturer, we will provide you with the safest and most economical solution. If you want to be interested in our products, please contact customer service for more information.